Durable metal construction with high-efficiency and low-restriction across the range. For installation on loaders, graders, crushers, haulers, mixers, and mining machines.

turbo® II Precleaner Highlights

- Extends engine air filter life

- “Top Down” air flow design

- 100-1100 CFM

- 4 sizes offered

- Self-powered and self-cleaning

- Reduces engine wear and prolongs engine life

- Maintains effective engine breathing for maximum efficiency and power

- Minimizes costly down time

- Easy install

- Heavy duty stainless steel band clamp

turbo® II performs its job in the toughest environments day in and day out. The unique design is all about preventing micro-abrasive dust from entering the machine’s engine creating cleaner air to prolong the engine life. turbo® II is the industry standard precleaner by which all precleaners are judged.

From its durable metal construction to its high efficiency and low restriction across the entire range, turbo® II is chosen worldwide by equipment operators for installation on loaders, graders, crushers, haulers, mixers, and mining machines. Anywhere a high level of protection is needed and where dust is an issue, the turbo® II is a must.

Contact our Sales Team

To get pricing, place an order, or to find out more technical information and specifications, contact our Sales Team.

Model Variants & Part Numbers

Description/ Size

Model 24 – 3″

Model 24 – 4″

Model 35

Model 46 – 4 1/2″

Model 46 – 5″

Model 46 – 6″

Model 46 – 7″

Model 68 – 6″

Model 68 – 7″

Model 68 – 8″

Model Number

21-1024000

21-1024015

21-1035000

21-1046000

21-1046001

21-1046002

21-1046003

21-1068001

21-1068002

21-1068003

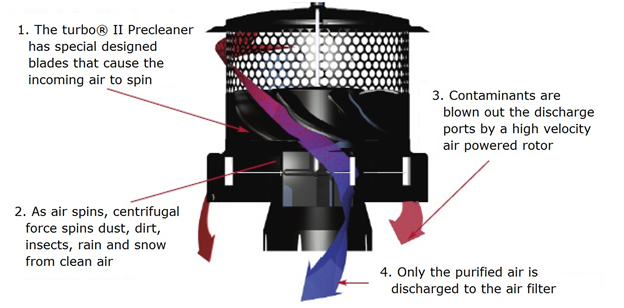

turbo® II Patented Design

The patented metal designed turbo® II is the only metal precleaner that offers a “Top Down” air flow by drawing dirty air through the protective screen at the top of the unit. turbo® II Precleaners have aerodynamically designed overlapped vanes that force the incoming air to spin and causing separation of dust and dirt from the air by centrifugal force. The dust and debris then spins down the wall of the main chamber and into the blower chamber where the high velocity spinner forces the dirt to the discharge ports at the base of the unit. As the velocity of the primary air stream increases, it ejects out additional dirt and debris providing the cleanest possible air to the filter element. This design offers exceptional balance between added restriction and efficiency.

Model Information

turbo® II is currently manufactured in four sizes and covers a CFM range from 100 to 1100 CFM. Additionally, turbo® II offers a similar model made out of high strength glass-reinforced polymer that is lighter in weight and easier to install, the turbo® III. All turbo® Precleaners are independently tested to industry SAE J726 and ISO 5001 standards.

Contact our Sales Team

To get pricing, place an order, or to find out more technical information and specifications, contact our Sales Team.